Versatile Solutions for Automated Cap Sealing in Production Lines #

The intermittent motion automatic cap sealing machine is engineered to meet the needs of medium-volume production environments, offering flexibility for a wide range of bottle shapes and cap types. This equipment is suitable for both standalone operation and seamless integration into existing production lines.

Key Features and Capabilities #

-

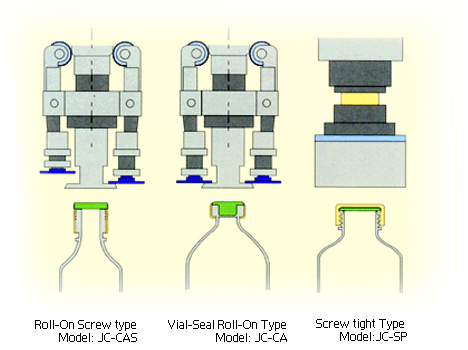

Adaptable Cap Sealing Operations:

- Supports roll-on screw caps, vial-seal roll-on, plastic cap screw-tightening, and press-on cap operations, making it suitable for diverse packaging requirements.

-

Robust and Hygienic Construction:

- The conveyor belt, as well as the machine’s top and side covers, are constructed from stainless steel. This ensures not only a sleek appearance but also facilitates easy cleaning, maintenance, and long-term durability.

-

Efficient Changeover and Operation:

- Quick and straightforward size changeover is enabled by the easy replacement of the star wheel and sealing head, accommodating various bottle sizes with minimal downtime.

-

Enhanced Control and Safety:

- Stepless speed control allows for precise adjustment of motor speed to match production needs.

- A shock-absorbing device in the sealing head base helps reduce bottle breakage rates during operation.

- The integrated torque adjustment device provides reliable control over the tightness of the seal, ensuring product integrity.

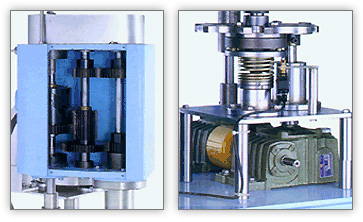

Image Gallery #

Additional Information #

- Motor Speed Adjustment: Freedom to fine-tune production speed with a stepless speed controller.

- Shock Absorption: Reduced risk of bottle breakage due to a shock-absorbing device in the sealing head base.

- Torque Control: Adjustable torque device for precise sealing tightness.

- Quick Changeover: Easy replacement of the star wheel and sealing head for different bottle sizes.

- Versatility: Suitable for a variety of bottle and cap types, supporting both individual and in-line production setups.

For further details or to discuss your specific requirements, please contact Chin Yi Machinery Co., Ltd. or Likai Induction Technology Co., Ltd. via the information provided on the website.