Precision and Efficiency in Liquid Bottle Filling #

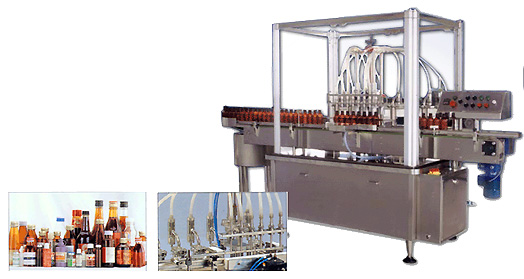

The automatic bottle liquid filling machine utilizes a volumetric piston filling mechanism, ensuring precise and consistent filling for a wide range of liquid products. Engineered as a straight-line model, this system offers smooth, fully automated bottle feeding, positioning, and filling processes, all in compliance with GMP standards. Its user-friendly operation and high accuracy make it an ideal choice for industries such as pharmaceuticals, personal care (shampoo), detergents, and other liquid chemical applications.

Key Advantages #

- Air-Controlled Positioning: The machine employs air-controlled mechanisms for bottle positioning, resulting in quiet operation and simplified maintenance.

- Rapid Bottle Size Changeover: Adjustments for different bottle sizes can be made quickly and without the need for additional change parts, minimizing downtime.

- No-Bottle-No-Filling System: Integrated safety features ensure that filling only occurs when bottles are correctly positioned, enhancing operational reliability.

- Accurate Volume Adjustment: Filling volumes can be set in a single step or fine-tuned with micro-adjustments, delivering high accuracy and minimal error.

- Hygienic Construction: All liquid-contact components are manufactured from SS#316 stainless steel, supporting easy cleaning and compliance with GMP requirements.

- Simple Installation and Cleaning: The design allows for straightforward assembly and disassembly, facilitating routine maintenance and sanitation.

Technical Features #

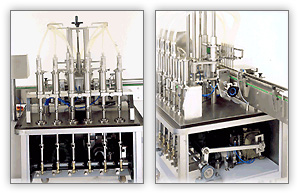

- Individually Controlled Cylinders: Each filling cylinder is independently controlled, enabling fast and precise volume adjustments.

- Durable Stainless Steel Construction: Both the conveyor and machine top surface are made from stainless steel, ensuring durability and ease of cleaning.

- Air-Controlled Bottle Handling: Bottle feeding and positioning are managed by air controls for smooth and reliable operation.

- Stepless Speed Control: The motor speed can be freely adjusted using a stepless speed controller, allowing for flexible production rates.

- Versatile Integration: Suitable for standalone use or integration into a complete production line, including compatibility with automatic cap sealing machines.

Product Applications #

This automatic liquid filling machine is engineered to meet the needs of various industries, including pharmaceuticals, cosmetics, household chemicals, and more. Its robust design and flexible operation make it a valuable asset for any production environment requiring precise and hygienic liquid filling.

For further information or to discuss your specific requirements, please refer to the contact details provided on the website.